What is a Decibel?

The decibel (dB) is a unit used to express the energy in a sound wave.

How is a Decibel Measured?

The measurement of a decibel is a logarithmic scale measurement. Named in honour of Alexander Graham Bell and originally used to measure output along telegraph cables it expresses a ratio or comparison of two quantities. One decibel is one tenth of one bel and is the common reference name.

Measuring to Protect our Hearing.

Used for acoustic purposes or defining how loud a sound is to the human ear the dB expresses sound pressure level. This gives us an indication of what the human ear can tolerate or how sensitive our hearing is to certain levels of noise. Knowing the levels that the human ear can tolerate and how long it will take to cause damage allows us to take preventative measure to protect our hearing. Being able to measure the dB levels of equipment, vehicles, and sound producing objects gives us an advantage to know what we need to avoid or how long we are able to tolerate certain levels of noise.

Starting at the lowest level or the quietest thing that can be heard the decibel is expressed as 0 or 0dB. At levels over 85dB hearing loss or tinnitus can occur. At the pain level or very loud level the decibel is expressed as 120dB. Over 140dB can cause immediate and irreparable damage.

Noise level X exposure level

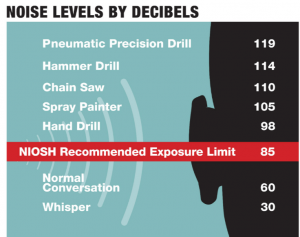

Being exposed to decibel levels below 80dB will rarely be a cause for hearing concerns. However, being exposed to higher level can definitely be concerning. The higher the level, the shorter the time exposure will be before noise induced damage will take effect. The National Institute for Occupational Safety and Health (NIOSH) suggests time frames for safety exposure.

- At levels of 85dB hearing damage can occur after 8 hour exposure

- At levels of 90dB hearing damage can occur after 2 hours of exposure

- At levels of 94dB hearing damage can occur after 1 hours of exposure

- At levels of 100dB hearing damage can occur within 15 min of exposure

- Over 112 dB hearing damage can be immediate and permanent

To get an idea of what dB levels are for different noises and what effect they can have on your hearing see the chart below:

-

Normal Breathing 10 dB

-

Normal conversation 50-65 dB

-

City traffic noise 80 dB

-

Lawn Mower 85-90 dB

-

Garbage Truck 100 dB

-

Jackhammer 110 dB

-

Stereo or headset 110 – 130 dB

-

Rock Concert 120-140 dB

What decibel levels are you exposed to? What length of time are you exposed to them for? Protect your hearing. Contact Us to learn how you can protect your hearing and prevent hearing loss due to noise

d to be manufactured but the one similarity is the use of a layering process.

d to be manufactured but the one similarity is the use of a layering process.