Sound is an integral part of our lives, and understanding how we measure it is crucial for our well-being. Let’s dive into the fascinating realm of decibels (dB) and Noise Reduction Ratings (NRR), uncovering how these measurements play a vital role in different aspects of our daily experiences.

🔹 Decibels (dB):

- Sound Level: Picture the serene ambiance of a library at 30 dB and contrast it with the booming energy of a rock concert hitting 110 dB. Decibels quantify sound intensity, offering us a scale to gauge the sonic landscapes around us.

- Hearing Protection: In noisy workplaces, earmuffs equipped with a 25 dB noise reduction act as silent guardians, transforming a clamorous environment into a safe haven shielded by auditory armor. 🛡️

🔹 Noise Reduction Rating (NRR):

- Earmuffs & Earplugs: Have you ever spotted those NRR ratings? Whether it’s earmuffs boasting an NRR of 28 dB or foam earplugs and personal hearing protectors with an NRR of 32 dB, these become your trusted allies in the realm of silence. 🎧

- Occupational Safety: The Occupational Safety and Health Administration (OSHA) sets the safety benchmark at 90 dB over an 8-hour workday, ensuring workplaces remain conducive to well-being.

🔹 Hearing Damage:

- Beware! Prolonged exposure to sounds surpassing 85 dB can result in permanent hearing damage. Protecting those precious ears becomes paramount!

🔹 Music & Entertainment:

- Ever wondered how concert sound systems achieve that immersive experience? Sound engineers meticulously measure and control sound levels in decibels, letting you feel the music at an electrifying 120 dB. 🎵

These examples underscore the pivotal role of decibels and NRR ratings in comprehending and safeguarding our hearing in diverse scenarios. If you’re curious to explore more about Noise Reduction Ratings (NRR) and how they can be estimated, check out this insightful resource: NRR Estimation Systems

Stay tuned for a symphony of sound wisdom!

#SoundScience #NoiseReduction #ProtectYourEars #CustomProtectEar #ProtectEar #dBBlockers #NRR

disposables to custom hearing protection. However, when it comes to quality it is important to look at two elements; 1. adequate protection and 2. communication safety. When it comes to hearing protection, not all devices are created equally.

disposables to custom hearing protection. However, when it comes to quality it is important to look at two elements; 1. adequate protection and 2. communication safety. When it comes to hearing protection, not all devices are created equally.

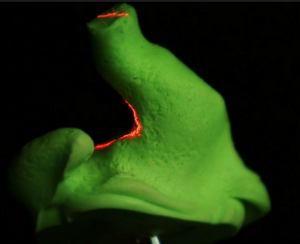

d to be manufactured but the one similarity is the use of a layering process.

d to be manufactured but the one similarity is the use of a layering process.

company’s representatives take impressions of each worker’s ear canal and outer ear and train workers on how to ensure proper fit. Greater comfort addresses the problem facing health and safety managers of getting people to wear hearing protection and policing their use. A filter and vent in the db Blockers can make speech more understandable by reducing attenuation at higher speech frequencies.

company’s representatives take impressions of each worker’s ear canal and outer ear and train workers on how to ensure proper fit. Greater comfort addresses the problem facing health and safety managers of getting people to wear hearing protection and policing their use. A filter and vent in the db Blockers can make speech more understandable by reducing attenuation at higher speech frequencies.